Could a routine check save your production line or stop a cold morning from turning costly? We ask this because unexpected shutdowns often cost more than planned maintenance.

We are Lord Mechanical LTD, your local experts serving North Vancouver and West Vancouver. We combine technical knowledge with clear guidance so you can make confident decisions for your home or business.

Our approach is practical and data-backed. We assess units, clean and repair plate, shell-and-tube, hairpin, and fin-fan systems, then advise on intervals that prevent surprise outages.

We focus on quality at every step — from OEM-grade gaskets to documented inspections — so you can trust performance after the work is done. Need immediate help? Call 604-670-3737 and we’ll triage by phone, recommend the fastest path to stabilise your unit, and schedule prompt attendance.

Key Takeaways

- We are a Vancouver-based team offering end-to-end solutions for homes and businesses.

- Routine maintenance costs less than unexpected downtime.

- We use data-backed methods and OEM materials for lasting quality.

- We provide clear timelines, transparent pricing, and tailored recommendations.

- Call 604-670-3737 for fast triage and scheduling across North and West Vancouver.

Trusted heat exchanger services tailored for Vancouver clients

Our Vancouver team builds plans that match local water chemistry, building use, and downtime windows.

We serve homes, commercial sites, and industrial facilities across the Lower Mainland. You get rapid on-site repair and cleaning, backed by large shop capacity in the GTA and Edmonton for faster turnarounds.

We offer performance audits, planned maintenance, and plate reconditioning. This helps you decide whether the unit needs targeted cleaning, regasketing, or a full rebuild.

What we do for you

- Right-sized plans based on local water quality and usage patterns.

- A single point of contact for updates, scheduling, and post-job reports.

- Shop prep to shorten onsite work and reduce your downtime.

- Benchmarks and clear recommendations rooted in operational experience.

Need immediate attention? Call 604-670-3737 to book an inspection or quote and schedule your next project with confidence.

Comprehensive heat exchanger services

Our team delivers a clear menu of repair and upkeep options that match local schedules and equipment needs. We help you decide whether a targeted clean, a partial rebuild, or full fabrication is the right path.

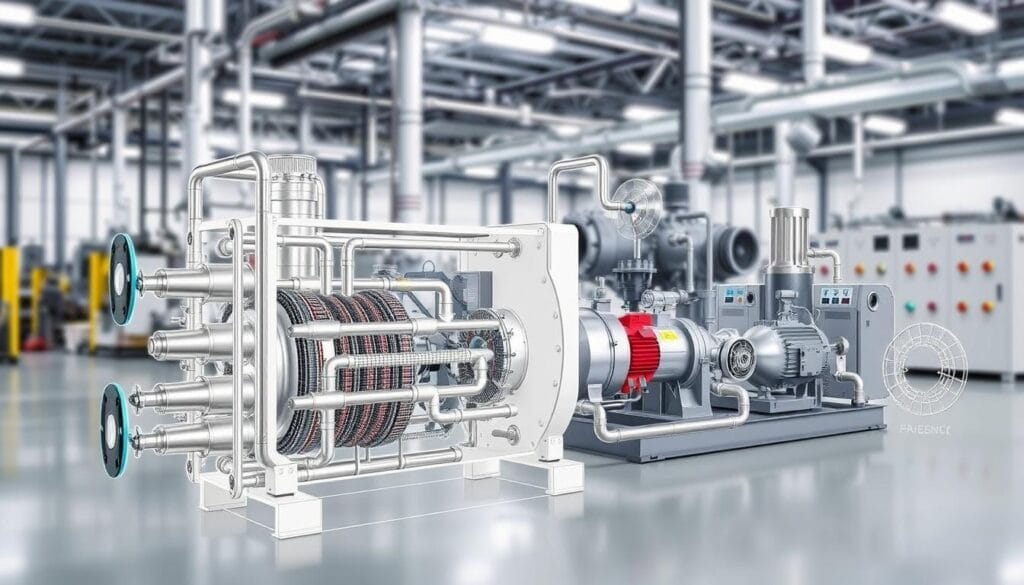

Heat exchanger repair: plate, shell & tube, hairpin, and fin-fan

We repair plate and shell-and-tube units and support hairpin and fin-fan repair work. Repairs restore transfer efficiency and stabilise process control.

Heat exchanger maintenance and cleaning to minimize downtime

Planned maintenance plans fit your operating calendar to reduce unplanned stoppages. Professional cleaning—from chemical plate baths to mechanical bundle work—removes fouling that chokes flow and cuts performance.

Inspection and performance audits for reliable operation

We run audits to spot bottlenecks, recommend corrective steps, and track improvements over time. Reports include measurable findings so you can compare before and after.

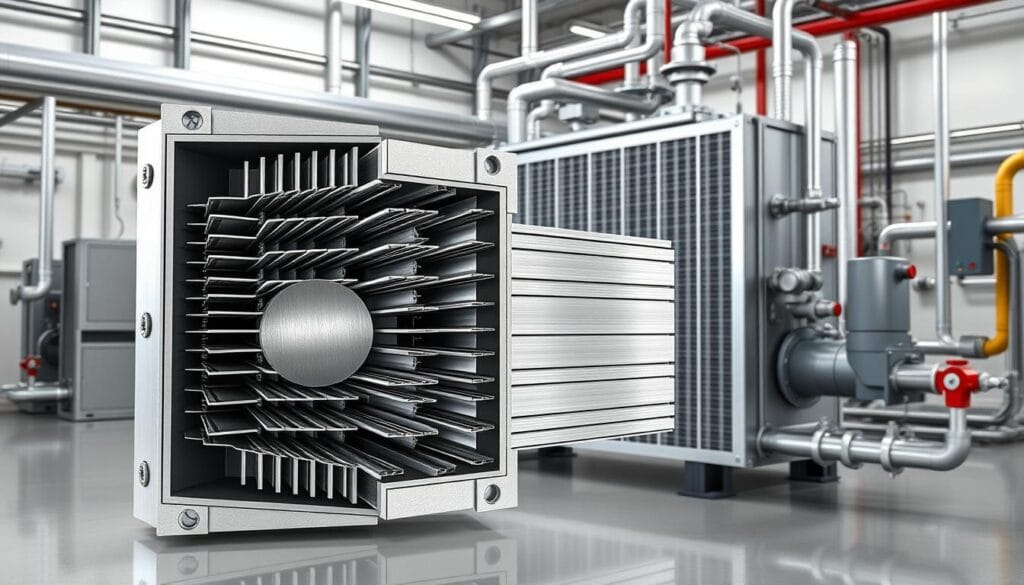

Refurbishment and component replacement

We replace gaskets, bolts, and connection linings and offer refurbishment options that extend equipment life. Certificates of Compliance and material traceability are provided when applicable.

Fabrication and bundle manufacturing support

For complex projects we coordinate bundle fabrication to OEM tolerances and perform QC to ASME Sec. VIII Div. 1 & 2. This keeps design duty intact and speeds return to service.

- Options: cleaning, regasketing, or full refurbishment with cost-benefit guidance.

- Documentation: service reports, Mill Certifications, and compliance paperwork.

- Fast booking: Call 604-670-3737 to schedule an inspection or repair window.

Maintenance and repair expertise that reduces downtime

Quick, methodical maintenance reduces unplanned stops and extends equipment life. We explain technical steps in plain terms and tell you when to act to avoid bigger issues.

Plate cleaning process

Our plate cleaning follows a proven sequence: remove gaskets, descale and soak plates in a controlled acid bath, then rinse. We use UV inspection to find pinholes or cracks before installing new gaskets.

Regasketing and materials

We fit OEM-grade gasket materials and use correct bonding methods. Gaskets are heat set to ensure adhesion and reliable sealing before we reassemble the plate pack to drawing specs.

Onsite support and signals to act

When product temperatures drift or pressure varies, call us. Those are classic signs of fouling or gasket failure that can cascade into larger problems.

| Task | What we do | Benefit |

|---|---|---|

| Plate cleaning | Degasketing, acid soak, rinse, UV inspection | Restores flow and transfer |

| Regasketing | OEM gaskets, heat set, alignment check | Reduces leaks and rework |

| Emergency turnarounds | Onsite crews, spare pack swaps | Minimizes downtime |

Inspection steps are documented so you can see whether cleaning, repair, or replacement is right. For immediate support, call 604-670-3737 — we prioritise urgent jobs to protect your operation.

Specialised technologies and quality assurance you can count on

Advanced machining and joining methods give you repeatable results and lower risk on complex repairs. We select equipment and processes to match metallurgy and duty so you get predictable outcomes.

Precision CNC drilling, orbital welding, and controlled tube expansion

We use precision CNC drilling and orbital welding to deliver consistent tube-to-tubesheet joints. This reduces leak risk during thermal cycling.

High-pressure hydraulic and Matex variable-speed tube expansion seat tubes without excessive work hardening. That extends life and safeguards heat transfer.

Run-pull tooling and bundle saw cutting for faster re-tubes

Run-pull technology and tube bundle saw cutting speed re-tubes on shell units. Faster turnarounds mean shorter outages and lower process risk.

QC inspections to ASME Sec. VIII Div. 1 & 2 with traceable documentation

All fabricated components get formal inspection with Certificates of Compliance. Reports show material heat numbers, thickness checks, and measured tolerances.

We show you exactly how advanced methods reduce risk and improve outcomes, so you can approve work with confidence.

| Technology | What it fixes | Standard / Benefit |

|---|---|---|

| Precision CNC drilling | Accurate tube alignment | Reduced leaks, consistent tolerances |

| Orbital welding | Secure tube-to-plate joints | Repeatable quality under cycling |

| Hydraulic & variable-speed expansion | Firm tube seating, less work hardening | Longer life, better heat transfer |

| Run-pull & saw cutting | Faster re-tubes | Shorter outages, documented inspection |

Call 604-670-3737 for a technical consult and to discuss fabrication options, inspection needs, or bespoke equipment planning. We prioritise quality and clear reports so you can approve repairs with confidence.

Field service coverage and rapid turnarounds across Canada

We stage parts and shop work in advance so onsite windows stay short and predictable.

24/7 field support is available from coast to coast. Our crews respond to urgent calls any time, coordinating Scarborough and Edmonton repair centres to prep shop work before we arrive.

We prioritise North Vancouver and West Vancouver dispatch while using national resources for complex projects. That mix speeds turnarounds and keeps your project on schedule.

24/7 field services with coordinated shop preparation

- We pre-assemble gasket kits, cleaning media, and test fixtures so we spend less time onsite.

- Mission-critical work gets shift coverage and safety walk-throughs for continuous progress.

- Before work begins, you receive a clear schedule, scope, and contingency plan.

- After the job, we debrief with actionable next steps and a tailored maintenance calendar.

“Fast staging and coordinated planning compress downtime and protect operations.”

For immediate field deployment or to coordinate an expedited plan, call 604-670-3737.

Equipment, brands, and industries we service

We identify your unit quickly so parts can be confirmed before any work is scheduled. This prevents ordering errors and shortens lead times for cleaning, maintenance, or fabrication.

Supported brands: Alfa Laval, GEA, Funke, Sondex, Tranter, SWEP and many others. We support common plate patterns and frame types so we can work on your installed base without long learning curves.

Industries we serve include HVAC, food & beverage, power generation, chemical, pulp & paper, refrigeration, metals, and mining. Each sector has different duty cycles and cleaning requirements; we match parts and chemistry to those needs.

- We confirm model IDs, plate counts, and elastomer specs up front to avoid delays.

- Inventory access covers gasket materials and frame repairs—bolts, connection linings, and mechanical refurbishment.

- Where fabrication or bundle assistance is needed, we coordinate to OEM tolerances for reliable returns to service.

We advise clients on cost-effective choices: parts-plus-cleaning, full regasketing, or fabrication based on condition and operating targets.

Share your plate count and brand; we’ll verify lead times and schedule service at 604-670-3737.

Get solutions fast: book your project or inspection today

We make it simple to get your system back to spec. Reach us for same-day triage and a phone-scoped plan that speeds field response. We commit to fast quoting, clear timelines, and local expertise across North and West Vancouver.

Call 604-670-3737 for immediate service, parts, or a maintenance plan. Our team is available 24/7 to assess symptoms, confirm model details, and recommend the fastest route to restore performance.

How we help you quickly

- Speak with our team now at 604-670-3737—describe symptoms and brand so we can scope the project by phone.

- Book an inspection to confirm fouling, gasket wear, or flow restrictions before they affect building heat or production.

- We dispatch field crews with the right equipment and parts for onsite cleaning, regasketing, or repairs.

- Choose cleaning-only, regasketing, or refurbishment based on findings, budget, and availability windows.

- We schedule work around production hours and home heating needs to minimise disruption.

- For urgent cases we triage, stabilise, and complete corrective actions with documented results and warranty terms.

- Ask about a recurring maintenance plan to stay ahead of fouling and peak-season surprises.

- Prefer email? We’ll still call to confirm details and lock in times—604-670-3737.

| Need | Response | Typical timeline |

|---|---|---|

| Phone triage | Preliminary scope & parts check | Same day |

| Onsite inspection | Diagnosis, performance audit | 24–72 hours |

| Field repair or cleaning | Onsite cleaning, regasketing, part swap | 1–3 days (depends on scope) |

| Shop refurbishment | Reconditioning at central facility | 3–10 days (fast-track available) |

Conclusion

Timely inspections and targeted repairs prevent surprise outages and protect production and comfort.

Staying ahead of fouling with scheduled cleaning keeps transfer efficiency high and lowers energy waste. Proactive maintenance costs less than unplanned downtime.

We combine field response with ASME-aligned inspection and documented QA so your heat exchanger returns to duty with verified performance. Our fabrication and specialised methods speed complex repair and re-tube turnarounds.

If you are weighing repair versus replacement, we give a clear, data-backed plan that covers materials, timelines, and expected results. We tailor solutions for plate units and shell-and-tube exchangers to keep outages short.

Ready to move forward? Call 604-670-3737 to book inspection, discuss heat exchanger repair scope, and lock in your ideal project window across North and West Vancouver.